Propeller Propulsion Systems: From the dawn of aviation until today, propellers have been a cornerstone of aircraft propulsion systems. Their simple design, effective thrust generation, and economical operation have ensured their relevance across decades of technological advancements. This article delves into the intricacies of propeller propulsion systems, examining their development, working principles, types, and future prospects.

Propeller Propulsion Systems: Aircraft Propulsion

1. Historical Overview

The history of aircraft propulsion began long before the jet engine’s roar became synonymous with modern aviation. The Wright brothers’ first powered flight in 1903 utilized a propeller-driven system, marking the birth of an era dominated by propellers.

Initially, propellers were made of wood, hand-carved to suit individual aircraft. As aircraft designs progressed and demands on propellers increased, they evolved, utilizing newer materials and designs to improve efficiency and performance.

2. Principles of Propeller Propulsion

To understand propellers, it’s essential to grasp the basic principles behind their operation:

- Newton’s Third Law: The propeller works on this straightforward principle – for every action, there is an equal and opposite reaction. As the propeller blades rotate, they push air backward, and in response, the aircraft moves forward.

- Aerofoil Shape: Propeller blades are shaped like aerofoils, allowing them to generate lift, but in a forward direction, this ‘lift’ is what we refer to as thrust.

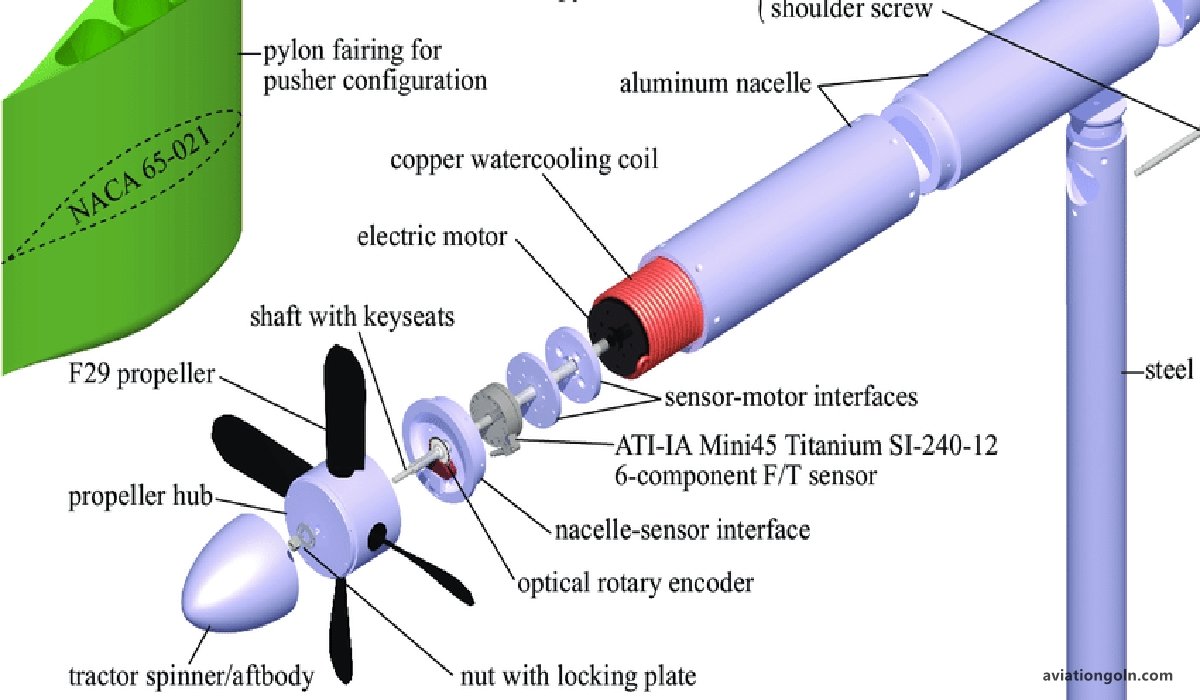

3. Components of Propeller Systems

- Blades: The primary component that interacts with the air. They are typically twisted, with a higher angle of attack at the hub and a lower one at the tip.

- Hub: The center of the propeller that holds the blades. It can be fixed or can allow variable pitch adjustments.

- Spinner: A conical component that covers the hub, improving aerodynamics and aesthetics.

4. Types of Propellers

a. Fixed Pitch Propellers

The simplest type, where the blades’ angle is set and cannot change. They’re typically used in smaller, general aviation aircraft due to their simplicity and lower cost.

b. Variable Pitch Propellers

The blade angle or pitch can be changed in flight or on the ground. This allows for optimizing performance in different flight conditions.

- Controllable Pitch Propellers: The pilot can adjust the blade angle during flight.

- Constant Speed Propellers: The blade angle automatically adjusts to maintain a constant RPM, beneficial for optimizing engine performance.

c. Contra-Rotating Propellers

These are two sets of propellers mounted on the same shaft but rotate in opposite directions. This design counteracts the torque produced by each propeller, leading to improved performance and efficiency.

5. Propeller Dynamics

a. Torque and P-factor

When a propeller rotates, it imparts a rotational force on the aircraft, known as torque. This force can cause the aircraft to roll in the opposite direction of the propeller’s rotation.

Additionally, when an aircraft is in a climb or high angle of attack, the descending blade of the propeller produces more thrust than the ascending blade due to its higher effective pitch. This asymmetry in thrust is termed the P-factor and can yaw the aircraft.

b. Efficiency

Propeller efficiency is the ratio of the useful power output (thrust times speed) to the power input from the engine. Many factors influence this, including the blade shape, pitch, and aircraft speed.

c. Tip Vortices

As the propeller rotates, the high-pressure air from beneath the blade tends to roll over the tip to the low-pressure region on top. This action creates swirling vortices, leading to drag and noise. Modern propellers often feature tapered or specially designed tips to minimize these vortices.

6. Advancements in Propeller Technology

a. Materials

The transition from wood to metal (usually aluminum) marked a significant step. In recent times, composite materials like carbon fiber have gained popularity due to their strength-to-weight ratio.

b. Noise Reduction

With increasing concerns over noise pollution, propeller designs aim for quieter operation. Scimitar-shaped blades, serrated tips, and other innovations have contributed to noise reduction.

c. Digital Control Systems

Modern propellers often incorporate digital systems to control blade pitch and monitor performance. Such systems ensure optimal efficiency and performance under varying conditions.

7. The Future of Propeller Propulsion

Even in the age of jets, propellers remain relevant. The rise of electric and hybrid-electric propulsion systems has given propellers a fresh lease of life. Electric motors’ characteristics pair well with propellers, offering quiet, efficient, and environmentally friendly options, especially for smaller aircraft and urban air mobility solutions.

Moreover, research continues to improve propeller materials, aerodynamics, and integration with new-age powerplants, ensuring their place in the future of aviation.

Propeller propulsion systems, with their rich history and continuous innovations, remain an integral part of aviation. Their adaptability to new technologies, coupled with their inherent simplicity and efficiency, ensures that the familiar swirl of the propeller will grace our skies for years to come.