Traditional and Composite Materials: The aeronautics industry has seen an evolutionary shift in the materials used in aircraft construction. From wood and fabric in the earliest aircraft to sophisticated composites in modern jets, the materials have evolved to meet the demanding requirements of strength, weight, durability, and cost. This article delves into the traditional materials used in aircraft structures and the emerging composite materials, highlighting their advantages, challenges, and future prospects.

Traditional and Composite Materials

1. Traditional Materials

a. Wood

The earliest aircraft, like the Wright brothers’ flyer, primarily utilized wood. Wood’s advantages are its low weight, natural resilience, and ease of repair.

Advantages:

- Low density: Wood is lightweight, making it ideal for aircraft where weight is a critical factor.

- Natural Flexibility: It can absorb minor stresses without breaking, providing a certain resilience to the structure.

Limitations:

- Susceptibility to Elements: Wood is vulnerable to moisture and can rot, compromising its structural integrity.

- Inconsistency: Natural variations in wood grain can introduce weak points.

b. Aluminum and Alloys

By the mid-20th century, aluminum alloys became the predominant materials for aircraft construction due to their strength-to-weight ratio.

Advantages:

- Strength-to-Weight Ratio: Aluminum alloys provide strong resistance to stresses while being lighter than most metals.

- Corrosion Resistance: Certain alloys, like the commonly used 7075, have a high resistance to corrosion.

Limitations:

- Fatigue: Over time, aluminum is susceptible to fatigue, leading to potential cracks.

- Conductivity: Aluminum is a good conductor of heat and electricity which can be a disadvantage in certain scenarios.

c. Steel

While heavier than aluminum, steel is used in aircraft parts that demand high strength, like landing gear.

Advantages:

- High Strength: Steel can withstand significant stresses.

- Durability: Properly treated steel can last for extended periods without degrading.

Limitations:

- Weight: Steel is heavier than aluminum, making it less suitable for primary aircraft structures.

- Corrosion: Steel is prone to rust if not properly treated.

2. Composite Materials

Composite materials consist of two or more materials combined to leverage the strengths of each, producing a superior material. In the context of aviation, composites often refer to fiber-reinforced polymers.

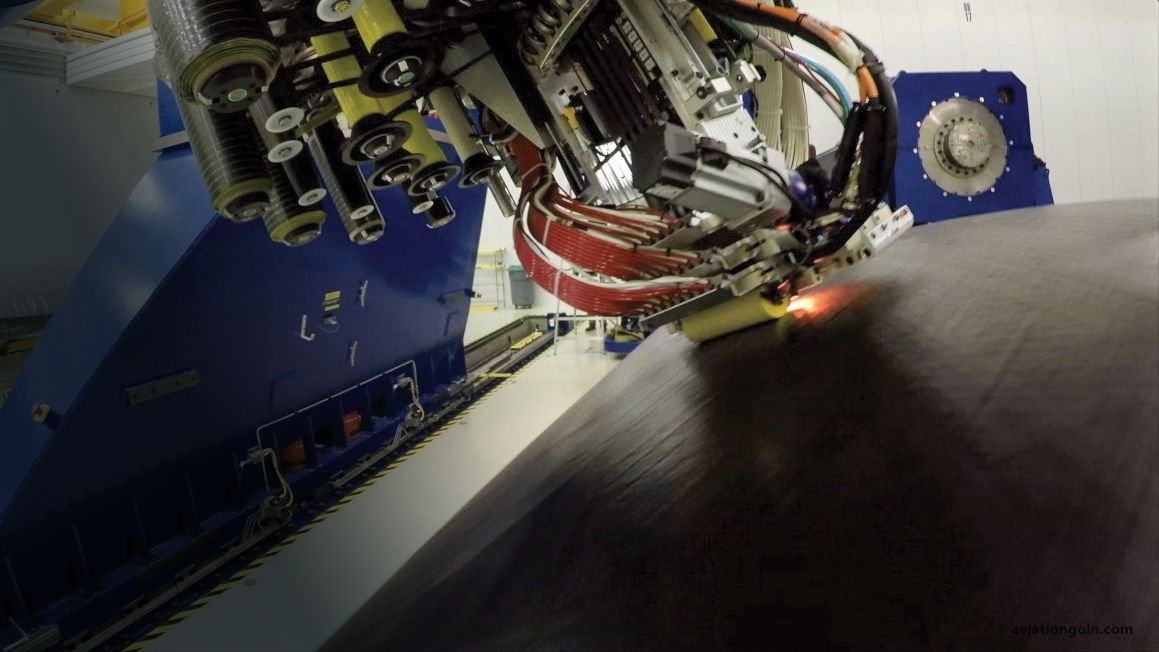

a. Carbon-Fiber Reinforced Polymers (CFRPs)

Carbon fibers embedded in a polymer matrix produce a lightweight, strong material ideal for aircraft structures.

Advantages:

- Strength and Weight: CFRPs offer a high strength-to-weight ratio, making them optimal for aerospace applications.

- Flexibility in Design: Composites can be molded into complex shapes, allowing for aerodynamic optimizations.

- Corrosion Resistance: CFRPs are inherently resistant to corrosion.

Limitations:

- Cost: Production of CFRPs can be expensive.

- Damage Detection: Unlike dents in aluminum, damages in composites can be hidden and hard to detect.

b. Glass-Fiber Reinforced Polymers (GFRPs)

Similar to CFRPs, GFRPs use glass fibers instead of carbon.

Advantages:

- Weight Savings: While not as strong as CFRPs, GFRPs offer significant weight advantages over traditional metals.

- Electrical Insulation: Glass fibers don’t conduct electricity, making GFRPs good insulators.

Limitations:

- Strength: GFRPs are not as strong as CFRPs and might not be suitable for all aerospace applications.

- Brittleness: Can be more brittle compared to other composites.

c. Other Composites

Other composites, such as Kevlar and boron-reinforced polymers, offer unique advantages but are less common than CFRPs and GFRPs.

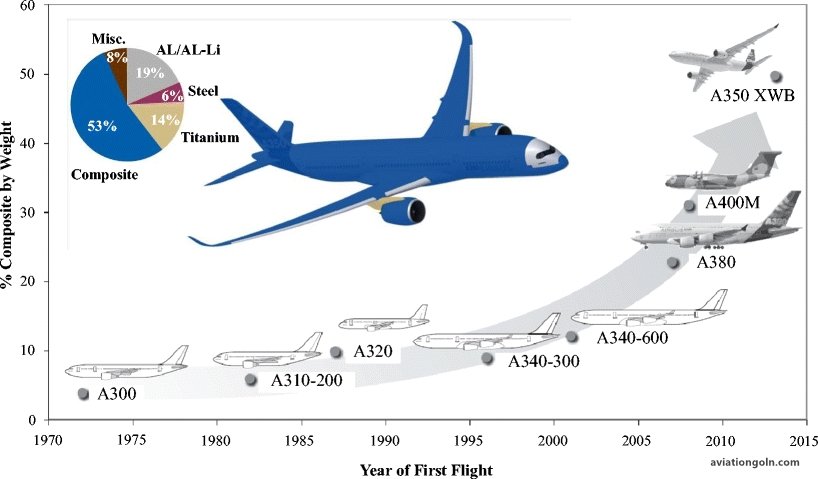

3. Transition to Composites in Modern Aircraft

Today’s commercial aircraft, like the Boeing 787 and Airbus A350, use composite materials extensively. This transition from traditional metals to composites has been driven by:

- Fuel Efficiency: Lighter aircraft consume less fuel.

- Maintenance Reduction: Composites’ resistance to corrosion can reduce maintenance needs and costs.

- Performance Improvements: Composites can be shaped and optimized for aerodynamic performance.

4. Challenges in Adopting Composites

While composites offer numerous advantages, the aviation industry faces challenges in their adoption:

- Inspection and Repair: Detecting and repairing damage in composite structures can be challenging.

- Recycling: Unlike metals, composites can be harder to recycle, raising environmental concerns.

- Training: The shift to composites requires retraining workers in manufacturing, maintenance, and repair processes.

The journey from wood to sophisticated composites in aircraft materials reflects the industry’s relentless pursuit of efficiency, safety, and performance. While traditional materials like aluminum still play a significant role, composites are undeniably shaping the future of aviation. As technology advances, the industry will continue to optimize materials for the unique demands of flight, ensuring safer, more efficient, and environmentally friendly air travel for the generations to come.