Hydraulic Systems in Aircraft Systems and Avionics: The marvel of modern aviation is not just about how an aircraft flies, but also how it manages complex actions while in the sky and on the ground. Underneath the sleek exterior of every aircraft, there lies a maze of interconnected systems working in harmony. One of the vital cogs in this intricate machine is the aircraft’s hydraulic system. This article dives deep into the heart of aircraft hydraulic systems, shedding light on their design, function, and undeniable importance in avionics.

Hydraulic Systems in Aircraft Systems and Avionics: Powering Flight Dynamics

1. Introduction to Hydraulic Systems

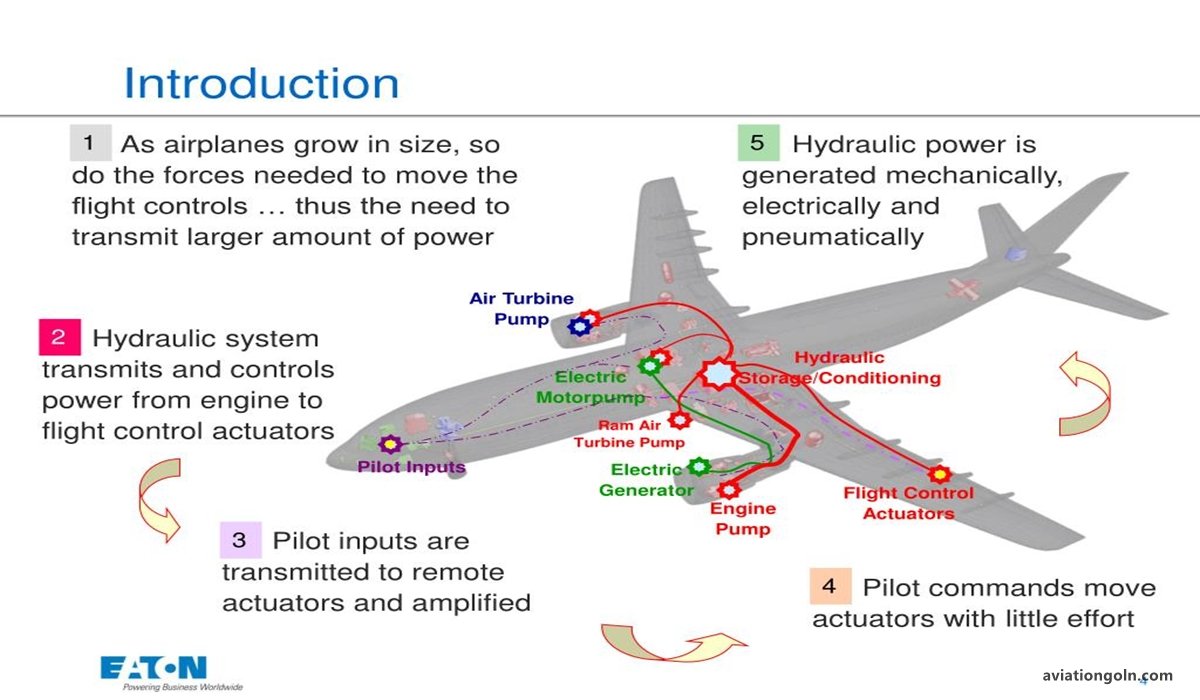

At its core, a hydraulic system uses pressurized fluid to transmit power. In aircraft, these systems are responsible for driving a wide range of functions, from moving control surfaces and retracting landing gear to operating brakes.

1.1 Why Hydraulics?

- Force Multiplication: A hydraulic system amplifies force, allowing small inputs to produce significant outputs.

- Reliability: These systems have fewer moving parts compared to mechanical systems, reducing wear and tear.

- Compactness: Hydraulic actuators and components are smaller and lighter than their mechanical or electrical counterparts.

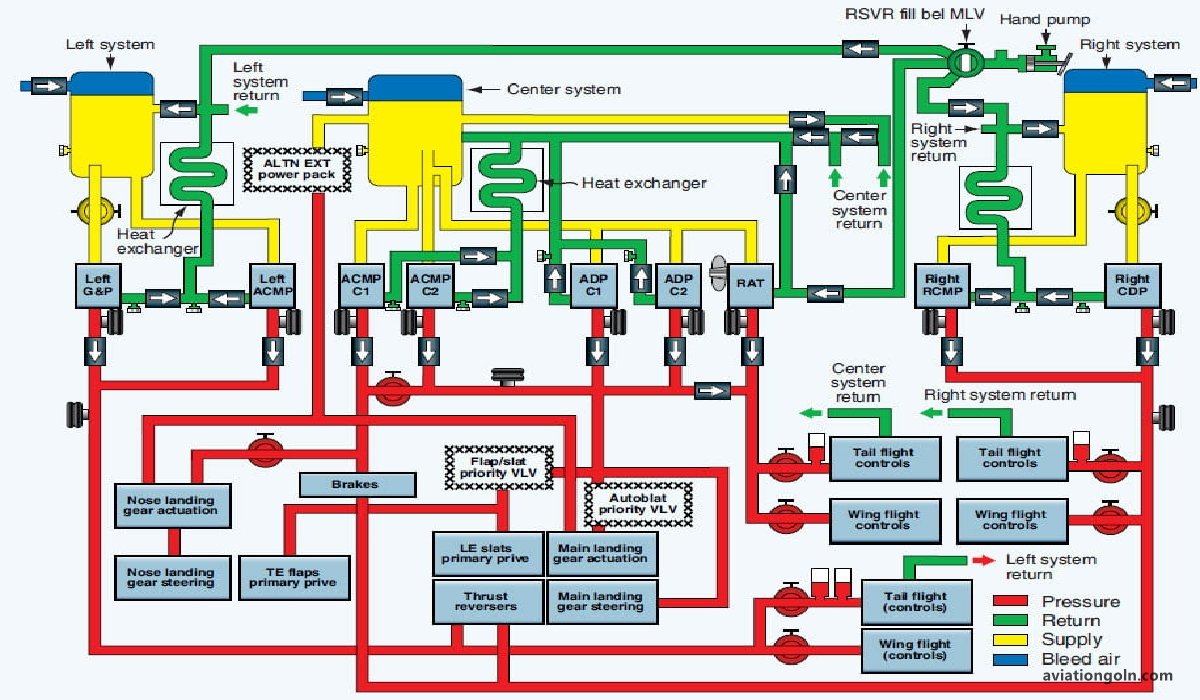

2. Components of an Aircraft Hydraulic System

2.1 Reservoir

This is where the hydraulic fluid is stored. It provides a source of fluid to the pump and compensates for fluid volume changes from temperature variations.

2.2 Pump

The pump draws hydraulic fluid from the reservoir and delivers it under pressure to the system. There are various pump types, including:

- Gear Pumps: Use intermeshing gears to pump fluid.

- Vane Pumps: Utilize moving vanes to move the hydraulic fluid.

- Piston Pumps: Employ reciprocating pistons to pump fluid.

2.3 Actuators

Actuators convert hydraulic energy into mechanical energy. They can be:

- Linear Actuators: Producing linear motion.

- Rotary Actuators: Producing rotational motion.

2.4 Valves

Valves control fluid direction, pressure, and flow rate. Common valve types include:

- Control Valves: Direct fluid flow.

- Relief Valves: Protect the system from overpressure.

- Shuttle Valves: Allow fluid flow from one of two sources.

2.5 Accumulators

Accumulators store hydraulic energy. They can:

- Smooth out pulsations.

- Supplement pump flow.

- Compensate for fluid leakage.

2.6 Filters

Filters remove contaminants from hydraulic fluid, ensuring the fluid’s cleanliness and longevity.

3. Function and Operation

In operation, the pump draws fluid from the reservoir and pressurizes it. This pressurized fluid then moves through the system, directed by various valves to different actuators. For instance, when a pilot wants to adjust the wing’s ailerons, they will actuate a control that opens a valve, allowing hydraulic fluid to flow into the appropriate actuator, moving the aileron.

4. Hydraulic Systems in Avionics

4.1 Brake Systems

Modern aircraft use hydraulically actuated brakes. When the pilot depresses the brake pedal, hydraulic fluid is directed to the brake assemblies, applying pressure to slow or stop the aircraft.

4.2 Flight Control Systems

Hydraulics is essential for moving primary control surfaces like ailerons, elevators, and rudders, especially in large aircraft where the aerodynamic loads are significant.

4.3 Landing Gear Systems

The retraction and extension of landing gear, especially in large commercial jets, rely on hydraulic systems.

4.4 Thrust Reversers

Many jet aircraft use hydraulic systems to actuate thrust reversers, helping to decelerate the aircraft upon landing.

5. Redundancy and Safety

Given the critical functions that hydraulic systems perform, redundancy is vital. Most large aircraft have multiple, independent hydraulic systems. If one system fails, others can typically perform the essential functions, ensuring continued safe operation.

6. Maintenance and Challenges

Hydraulic systems require regular maintenance to ensure:

- Fluid Cleanliness: Contaminated fluid can lead to component wear and failure.

- Seal Integrity: Leaking seals can result in reduced system efficiency and potential hazards.

- Component Inspection: Regular checks to ensure all components are functioning correctly.

7. The Future: Electromechanical and Electro-hydrostatic Actuators

Advancements in technology are leading to more electric aircraft designs, reducing reliance on hydraulics. Electromechanical and electro-hydrostatic actuators are emerging as alternatives, promising:

- Weight Reduction: Eliminating the need for hydraulic fluid and associated components.

- Increased Efficiency: Electric systems can be more energy-efficient.

- Reduced Maintenance: Fewer components can lead to reduced maintenance needs.

The unsung heroes of the aviation world, hydraulic systems, play a pivotal role in the safe and efficient operation of aircraft. From the gentle tilt of a wing to the forceful halt on a runway, they work tirelessly behind the scenes. As technology advances, so will the intricacies of these systems, paving the way for even safer, more efficient flight in the skies above.